At its core, a tech pack clearly communicates a particular garment's design and style requirements. It provides instructions for the clothing manufacturer to follow throughout production, including everything from pattern design to finishing. Because each process step is essential and requires proper instruction, the tech pack designer must clarify their instructions, directly affecting sample development and production. Each tech pack is unique and tailored to the garment's style and design requirements. In the following points, we'll outline how to create a tech pack and spec sheet for garments to ensure that all critical details are included.

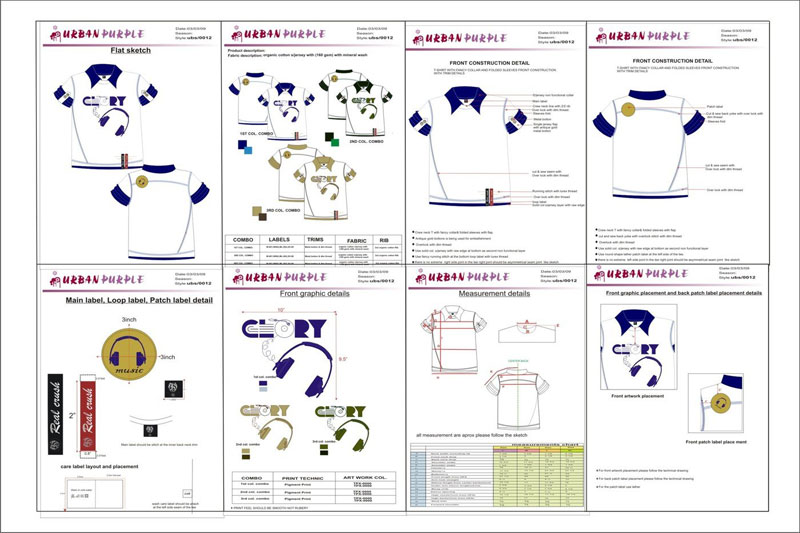

1. Fashion Flats: A Fashion Flat, also known as a Flat Sketch, is a front and back view of a garment that showcases every detail. It is the foundation for the tech pack design, so the designer must include all necessary information. The designer and the client should cross-check the Fashion Flat throughout the design process to ensure that all details are accurately represented.

2. Color Options and Pantone Code: Garment styles are incomplete without color options. Clients often request color variations for each style they design, allowing the brand to offer variety to its customers. Therefore, the tech pack designer should provide 2-3 color options for each style to ensure that the final product meets the client's expectations and offers flexibility for the brand.

3. Fabric Details: Fabric details are critical to any garment tech pack. This information includes the fabric's yarn count, weight, GSM, and composition and is essential for the garment manufacturer to estimate fabric consumption during production. The fabric details also determine the optimal quantity required at a particular price rate, which can impact the overall cost of production. Therefore, the tech pack designer should ensure that all fabric details are accurately included in the tech pack to avoid any issues during the production process.

4. Stitching and Construction Details: Stitching and construction details in a tech pack guide how a clothing manufacturer should stitch and construct the garment. The details show the step-by-step process of assembling the garment, and a tech pack designer with factory experience can provide the necessary expertise to ensure that these details are accurately conveyed. Therefore, including stitching and construction details in the tech pack is crucial to ensure the garment is produced correctly and meets the client's expectations.

5. Graphic and Print Details: Graphics and prints are essential to garment embellishment, and any garment style is complete with them. When incorporating prints and graphics, the placement and technique of the design are crucial to achieving the desired look. The tech pack designer must provide clear instructions for the print's color, size, and placement in the garment. Therefore, including these details in the tech pack is critical to ensure that the final product accurately represents the client's vision. A separate post will be dedicated to further discussing print and graphic details.

6. Graphic/Print Placement Details: Print design is a crucial aspect of tech pack design, but more is needed to create a design. Decisions on the placement of the print, such as whether it will be printed on a garment or a panel, are essential and should be made with the guidance of a technical designer. It's important to remember that even a good print can look like a disaster if placed in the wrong location on the garment. Therefore, the tech pack should include detailed measurements and the exact position of the print from a specific point to ensure that it's accurately executed during production.

7. Embroidery Details: Embroidery has become a popular trend in high-end fashion, and any garment style that features an embroidery design requires detailed instructions. The tech pack should include information on the type of embroidery, the number of stitches needed, the color of the thread, and other relevant details. The number of stitches required for a particular embroidery design is a crucial factor to consider. There are several embroidery techniques, such as puff embroidery, stiffly, and plain lock stitch, and the tech pack designer needs to specify the type of embroidery to be used in the design. Including these details in the tech pack ensures the embroidery is executed correctly during production.

8. Trims Detail: In addition to fabric, garments require other materials such as trims, including buttons, zippers, clip hooks, and more. Each garment style requires different trims, so providing complete details for sourcing and usage is essential. The technical designer must mention the trim details and specifications in the tech pack. For example, the tech pack should specify the button size for a shirt, and the zipper length should be mentioned for the bottom. Including these details in the design is crucial to ensure that the garment is constructed accurately and the style is executed as intended.

9. Branding Details: Every style a technical designer creates is typically for a brand, which should reflect specific branding details. Labels, hang tags, loop labels, and size labels are all part of a brand's identity. While these details may not be part of the tech pack design, it is essential to specify where to attach or stitch them in the tech pack. The most crucial branding trim is the care label, which provides instructions on handling the garment. Including these branding details in the tech pack ensures that the final product aligns with the brand's identity and guidelines.

11. Measurement Details and Size Chart: The measurement spec sheet includes all the critical measurements of the garment, such as the chest, waist, hip, sleeve length, and inseam, along with the tolerance range for each measurement. The size chart and grading rules are also essential to ensure the garment fits appropriately across all sizes. The tech pack designer must work closely with the pattern maker to ensure that the spec sheet is accurate and that the size chart and grading rules are appropriate for the target market.

12. Measurement Guideline: The measurement guideline is an essential part of the measurement spec sheet, as it provides clear instructions on how to take the measurements. It typically includes illustrations and descriptions of where to start and end the measurements and how to position the measuring tape. This helps to ensure that the measurements are consistent and accurate, which is crucial for achieving the desired fit of the garment.

13. Bills of Materials ( BOM ): A Bill of Materials (BOM) is a crucial document in the production process, as it lists all the materials and components required to make a garment. A Bill of Materials is an essential source of information used for production cost estimation. This includes the fabric, trims, hardware, labels, thread, and packaging materials. The production team uses the BOM to estimate the garment's cost and ensure that all the necessary materials are ordered and on hand before production begins. It is also used to keep track of inventory levels and provide sufficient critical components. Preparing an accurate BOM is an essential part of the tech pack design process and requires careful attention to detail and thorough knowledge of the garment's construction and materials.

Urban Purple offers comprehensive services for fashion brands, including design, sampling, production, and shipping. This can be valuable for brands looking for an end-to-end supply chain solution. Additionally, the Tech Pack Template Store can be a helpful resource for brands needing design spec sheet templates. Having a one-stop shop for all these services and resources can be a time-saving and cost-effective option for fashion brands.